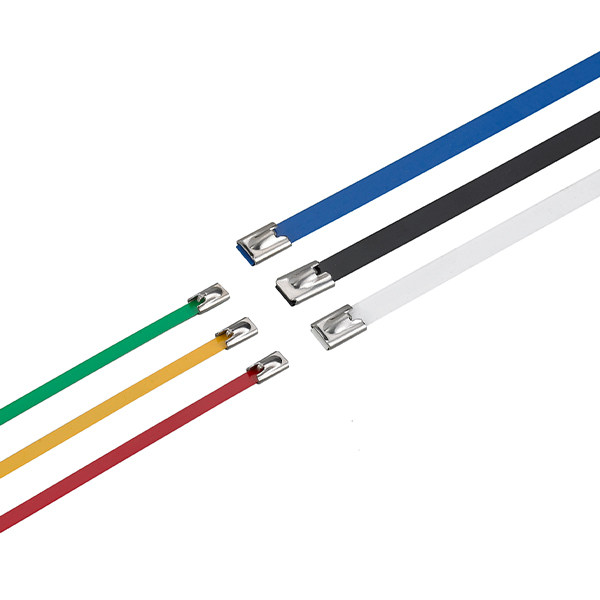

Product Decription:

Plastic coated Ball-lock Stainless steel cable ties are a type of fastening device made from stainless steel. Self-lock mode is the most effective way of securing cables. The tail of the cable tie can go through the self-lock mechanism buckle easily and quickly, and locked tightly.

Feature:

- The plastic coating provide additional surface protection. Prevent the corrosion between dissimilar material. The performance of corrosion resistant is better than the uncoated ties.

- Choice of color :Black, Red, Yellow, Blue, Green,white.

- Self-lock design is the most effective way of securing cables. The tail of the cable tie can go through the self-lock mechanism buckle easily and quickly, and locked tightly.

Technical Information:

- Width:4.6mm,7.9mm,10mm,12mm,16mm.

- Length: Can be customized.

- Corrosion Resistance: Stainless steel is resistant to rust, moisture, and other corrosive elements, making these cable ties suitable for use in harsh environments.

- High Tensile Strength: They can withstand significant tension, providing a secure hold even in demanding applications.

- Versatile: Available in various sizes, lengths, and styles, stainless steel cable ties can be used for a wide range of fastening needs.

- Easy Installation: They can be quickly and easily installed without the need for special tools.

- Long Service Life: The durability of stainless steel ensures that cable ties have a long service life, reducing the need for frequent replacements.

Application Fields:

- Electrical installations: Stainless steel cable ties are used to organize and secure electrical cables, wires, and conduit in both indoor and outdoor settings.

- Automotive: In the automotive industry, they help keep cables, hoses, and wiring harnesses in place, ensuring a neat and tidy engine compartment.

- Marine: Due to their corrosion resistance, stainless steel cable ties are ideal for marine applications, such as boat wiring and cable management.

- Construction: On construction sites, these ties can be used to fastening pipes, cables, and safety equipment.

- Industrial machinery: They are employed in industrial settings to bundle and secure cables, tubing, and components in machinery and equipment.

- Outdoor infrastructure: Stainless steel cable ties are suitable for outdoor applications

Technical Parameter:

| Item No. | Length | Width | Thickness | Max. Bundle Dia. | Min. Bundle Dia. | Min.Tensile Strength | Recommend Installation Tool | ||||||

| Inch | mm | mm | inch | mm | inch | mm | inch | mm | inch | lbs | kgs | ||

| STC-460100 | 100 | 3.9 | 4.6 | 1.8 | 0.25 | 0.01 | 25 | 1 | 12.7 | 0.5 | 220 | 100 | LKS-L1 LKS-338 |

| STC-460130 | 130 | 5.1 | 33 | 1.32 | |||||||||

| STC-460150 | 150 | 5.9 | 37 | 1.46 | |||||||||

| STC-460200 | 200 | 7.9 | 50 | 1.97 | |||||||||

| STC-460250 | 250 | 9.8 | 63 | 2.48 | |||||||||

| STC-460300 | 300 | 11.8 | 76 | 2.99 | |||||||||

| STC-460350 | 350 | 13.8 | 89 | 3.51 | |||||||||

| STC-460400 | 400 | 15.7 | 102 | 4.02 | |||||||||

| STC-460450 | 450 | 17.7 | 115 | 4.53 | |||||||||

| STC-460500 | 500 | 19.7 | 128 | 5.04 | |||||||||

| STC-460550 | 550 | 21.7 | 141 | 5.56 | |||||||||

| STC-460600 | 600 | 23.6 | 153 | 6.02 | |||||||||

| STC-460650 | 650 | 25.6 | 167 | 6.58 | |||||||||

| STC-460700 | 700 | 27.6 | 179 | 7.05 | |||||||||

| STC-460750 | 750 | 29.5 | 192 | 7.56 | |||||||||

| STC-460800 | 800 | 31.5 | 204 | 8.03 | |||||||||

| STC-460850 | 850 | 33.5 | 217 | 8.54 | |||||||||

| STC-460900 | 900 | 35.4 | 229 | 9.02 | |||||||||

| STC-460950 | 950 | 37.4 | 242 | 9.53 | |||||||||

| STC-461000 | 1000 | 39.4 | 255 | 10.04 | |||||||||

| STC-790130 | 130 | 5.1 | 7.9 | 0.31 | 0.25 | 0.01 | 33 | 1.32 | 12.7 | 0.5 | 500 | 220 | LKS-L1 LKS-338 |

| STC-790150 | 150 | 5.9 | 37 | 1.46 | |||||||||

| STC-790200 | 200 | 7.9 | 50 | 1.97 | |||||||||

| STC-790250 | 250 | 9.8 | 63 | 2.48 | |||||||||

| STC-790300 | 300 | 11.8 | 76 | 2.99 | |||||||||

| STC-790350 | 350 | 13.8 | 89 | 3.51 | |||||||||

| STC-790400 | 400 | 15.7 | 102 | 4.02 | |||||||||

| STC-790450 | 450 | 17.7 | 115 | 4.53 | |||||||||

| STC-790500 | 500 | 19.7 | 128 | 5.04 | |||||||||

| STC-790550 | 550 | 21.7 | 141 | 5.56 | |||||||||

| STC-790600 | 600 | 23.6 | 153 | 6.02 | |||||||||

| STC-790650 | 650 | 25.6 | 167 | 6.58 | |||||||||

| STC-790700 | 700 | 27.6 | 179 | 7.05 | |||||||||

| STC-790750 | 750 | 29.5 | 192 | 7.56 | |||||||||

| STC-790800 | 800 | 31.5 | 204 | 8.03 | |||||||||

| STC-790900 | 900 | 35.4 | 229 | 9.02 | |||||||||

| STC-791000 | 1000 | 39.4 | 255 | 10.04 | |||||||||

| STC-100200 | 200 | 7.9 | 10 | 0.39 | 0.3 | 0.012 | 50 | 1.97 | 12.7 | 0.5 | 618 | 280 | LKS-L1 |

| STC-100250 | 250 | 9.8 | 63 | 2.48 | |||||||||

| STC-100300 | 300 | 11.8 | 76 | 2.99 | |||||||||

| STC-100350 | 350 | 13.8 | 89 | 3.51 | |||||||||

| STC-100400 | 400 | 15.7 | 102 | 4.02 | |||||||||

| STC-100450 | 450 | 17.7 | 115 | 4.53 | |||||||||

| STC-100500 | 500 | 19.7 | 128 | 5.04 | |||||||||

| STC-100550 | 550 | 21.7 | 141 | 5.56 | |||||||||

| STC-100600 | 600 | 23.6 | 153 | 6.02 | |||||||||

| STC-100650 | 650 | 25.6 | 167 | 6.58 | |||||||||

| STC-100700 | 700 | 27.6 | 179 | 7.05 | |||||||||

| STC-100800 | 800 | 31.5 | 204 | 8.03 | |||||||||

| STC-120350 | 13.8 | 350 | 12 | 0.47 | 0.3 | 0.012 | 78 | 3.07 | 25.4 | 1 | 700 | 311 | LKS-L1 |

| STC-120400 | 15.7 | 400 | 102 | 4.02 | |||||||||

| STC-120500 | 19.7 | 500 | 128 | 5.04 | |||||||||

| STC-120550 | 21.7 | 550 | 141 | 5.56 | |||||||||

| STC-120600 | 23.6 | 600 | 154 | 6.02 | |||||||||

| STC-120700 | 27.6 | 700 | 180 | 7.05 | |||||||||

| STC-120800 | 31.5 | 800 | 206 | 8.03 | |||||||||

| STC-120900 | 35.4 | 900 | 228 | 8.98 | |||||||||

| STC-121000 | 39.4 | 1000 | 253 | 9.96 | |||||||||

| STC-121100 | 43.3 | 1100 | 278 | 10.94 | |||||||||

| STC-160600 | 23.6 | 600 | 16 | 0.63 | 0.3/ 0.4 | 0.012/ 0.016 | 148 | 5.83 | 25.4 | 1 | 700/900 | 311/410 | LQA-1 LKA-1 |

| STC-160750 | 29.5 | 750 | 184 | 7.24 | |||||||||

| STC-160900 | 35.4 | 900 | 220 | 8.66 | |||||||||

| STC-161100 | 43.3 | 1100 | 272 | 10.71 | |||||||||

Spray molding tie operation diagram