Product description:

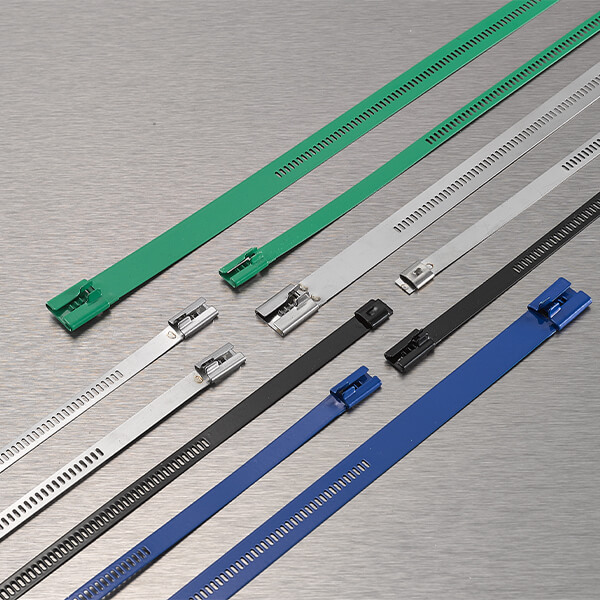

Ladder type Stainless steel cable ties are a type of fastening device made from stainless steel. They are commonly used in a variety of applications where a strong, durable, and corrosion-resistant fastening solution is required.

Product Feature:

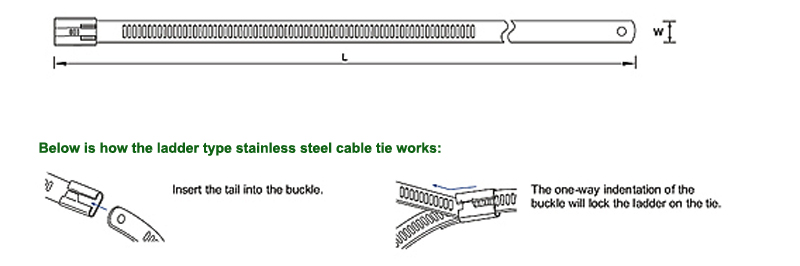

.Unique multi-locking mechanism design on the ladder strip can be applied without crimping tools.

Self-locking for fast, easy application.

.Extended ladder slot provides larger bundle diameter with the same length of tie.

.Large round slot at the tail-end allows application of hook-type tools.

.Uncoated tie for high temperature applications.

.Coated surface provides excellent chemical and weathering resistance, and superior insulation and protection of cables.

Material:

Stainless steel type:#201,#304 & #316.

Coating: PVC.

Application field:

- Electrical installations: Stainless steel cable ties are used to organize and secure electrical cables, wires, and conduit in both indoor and outdoor settings.

- Automotive: In the automotive industry, they help keep cables, hoses, and wiring harnesses in place, ensuring

- a neat and tidy engine compartment.

- Marine: Due to their corrosion resistance, stainless steel cable ties are ideal for marine applications, such as boat wiring and cable management.

- Construction: On construction sites, these ties can be used to fastening pipes, cables, and safety equipment.

- Industrial machinery: They are employed in industrial settings to bundle and secure cables, tubing, and components in machinery and equipment.

Outdoor infrastructure: Stainless steel cable ties are suitable for outdoor applications

Technical parameter:

| Item No. | Width | Length | Max. Bundle Dia. | Tensile Strength | Package | ||

| mm/inch | mm/inch | mm | inch | lbs | kg | pcs/bag | |

| 7×150 | 7/0.276 | 150/5.9 | 43 | 1.69 | 250 | 113.4 | 100 |

| 7×200 | 200/7.87 | 57.3 | 2.26 | 100 | |||

| 7×250 | 250/9.84 | 76.4 | 3.01 | 100 | |||

| 7×300 | 300/11.8 | 90.7 | 3.57 | 100 | |||

| 7×350 | 350/13.78 | 103 | 4.1 | 100 | |||

| 7×400 | 400/15.75 | 114 | 4.49 | 100 | |||

| 7×450 | 450/17.7 | 138.5 | 5.45 | 100 | |||

| 7×500 | 500/19.69 | 148 | 5.83 | 100 | |||

| 7×550 | 550/21.65 | 162 | 6.38 | 100 | |||

| 7×600 | 600/23.62 | 178 | 7 | 100 | |||

| 7×650 | 650/25.59 | 192 | 7.56 | 100 | |||

| 7×700 | 700/27.56 | 198 | 7.8 | 100 | |||

| 7×750 | 750/29.53 | 212 | 29.5 | 100 | |||

| 7×800 | 800/31.49 | 226 | 8.9 | 100 | |||

| 7×850 | 850/33.46 | 240 | 9.45 | 100 | |||

| 12×300 | 12/0.472 | 300/11.8 | 90.7 | 3.57 | 100 | ||

| 12×350 | 350/13.78 | 103 | 4.1 | 100 | |||

| 12×400 | 400/15.75 | 114 | 4.49 | 100 | |||

| 12×450 | 450/17.7 | 118 | 5.45 | 100 | |||

| 12×500 | 500/19.69 | 148 | 5.83 | 100 | |||

| 12×550 | 550/21.65 | 162 | 6.38 | 100 | |||

| 12×600 | 600/23.62 | 178 | 7 | 100 | |||

| 12×650 | 650/25.59 | 192 | 7.56 | 100 | |||

| 12×700 | 700/27.56 | 198 | 7.8 | 100 | |||

| 12×750 | 750/29.53 | 212 | 29.5 | 100 | |||

| 12×800 | 800/31.49 | 226 | 8.9 | 100 | |||

| 12×850 | 850/33.46 | 240 | 9.45 | 100 | |||

| 12×900 | 900/35.43 | 254 | 10 | 100 | |||

| 12×950 | 950/37.4 | 268 | 10.55 | 100 | |||

| 12×1000 | 1000/39.37 | 282 | 11.1 | 100 | |||