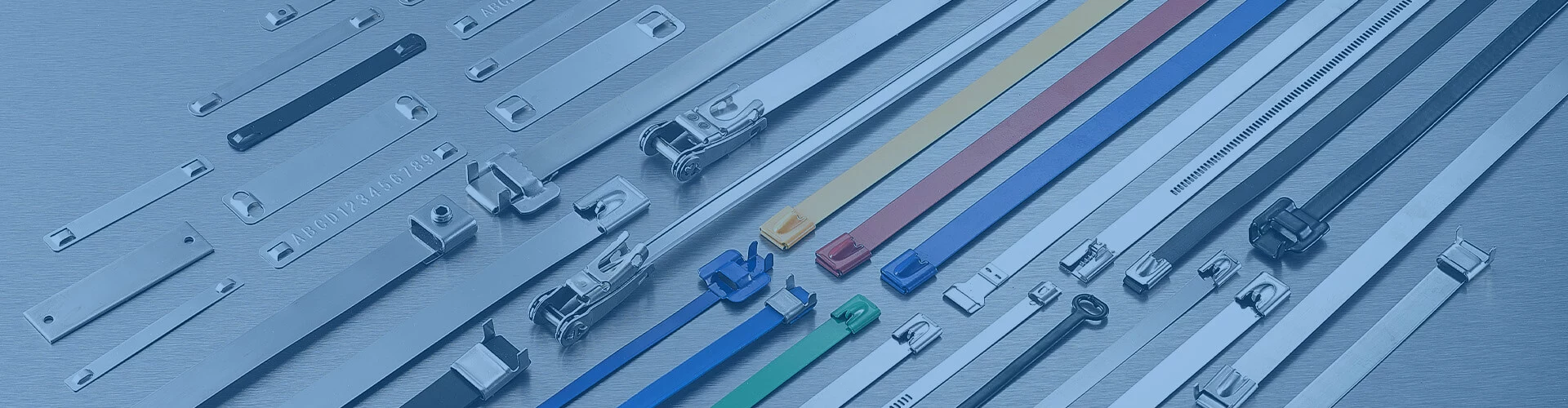

Today, there are many materials for cable ties, among which Stainless Steel Cable Tie has a high sales volume in the market. This is because compared with other cable ties, it has the advantages of good corrosion resistance, strong binding force and long service life. Its appearance brings great convenience to our life and work. Plastic-sprayed stainless steel cable ties are a common type of stainless steel cable ties. Pay attention to the following issues during use:

1. Choose high-quality plastic-sprayed cable ties. This can ensure the stability of the quality of the cable ties and prevent them from loosening. It can also reduce accidents caused by quality problems. You should also pay attention when choosing the color of the cable ties. Choose a color that matches the use environment.

2. Pay attention to the use environment of the cable ties. Some cable ties cannot be used in specific environments, such as certain chemical environments or high temperature environments, because the quality of the cable ties will change under these conditions, resulting in poor fixing effect. Therefore, before using plastic-sprayed cable ties, you should understand the environment and characteristics to which they are applicable and choose them carefully.

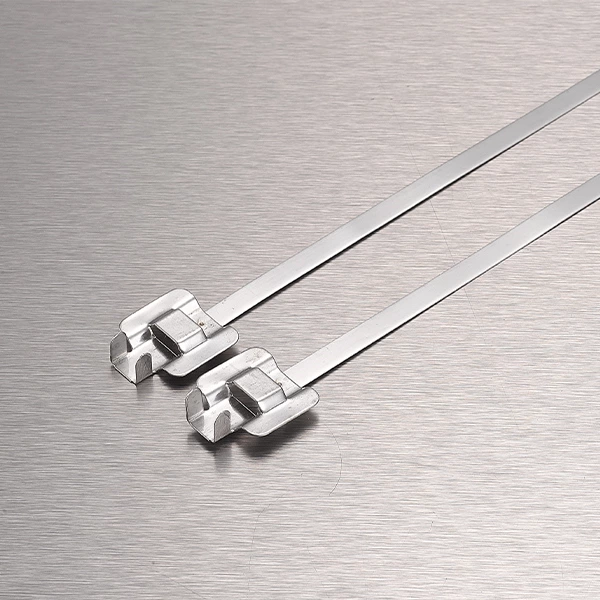

3. The length of the cable ties also needs to be paid attention to. Using cable ties that are too short will result in the inability to firmly fix items, and cable ties that are too long will waste materials. When using plastic-sprayed stainless steel cable ties, it is necessary to measure the required length according to the actual situation and choose the appropriate length of the cable tie.

4. Pay attention to the handling of the tail of the cable tie. If the tail of the cable tie is not handled well, it will not be fully utilized. When handling the tail of the cable tie, you can cut the tail into small pieces or wrap it around the cable tie to ensure that the tail is fully utilized and reduce waste.

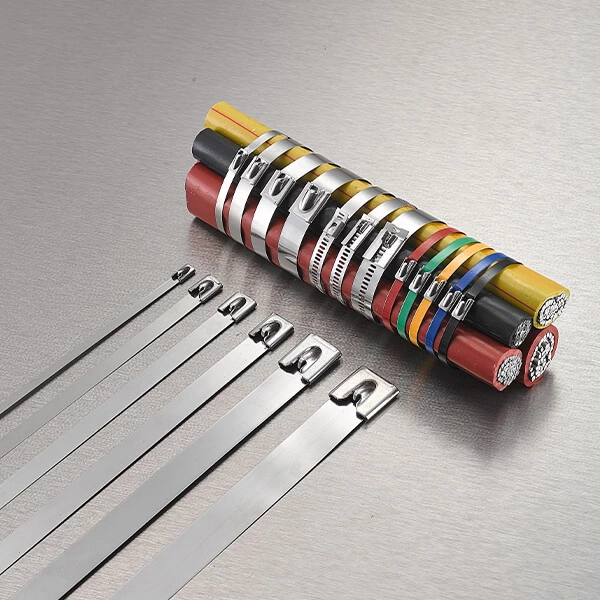

The corrosion resistance of plastic-sprayed stainless steel cable ties makes it particularly widely used in chemical, mechanical, aviation and other fields. In these industries, various pipes, wires, cables and other equipment are often needed, as well as cable ties that need to fix these equipment.

If ordinary metal cable ties are used, they are easily damaged because they cannot withstand the corrosion of patterns, toxic chemicals, acidic liquids and other substances, resulting in problems such as loose equipment fixation and loose wires and cables.

Using plastic-sprayed cable ties is different. Its outer layer is sprayed with a layer of high-density plastic, which gives it additional protection, enhances its corrosion resistance, and provides more reliable guarantees for the fixation of equipment.

As a common fixing tool, plastic-sprayed stainless steel cable ties are often used. In order to use them better, you should correctly choose the type and color of the cable ties during use, understand the use environment, measure the length reasonably, and properly handle the tail. Only by doing these things can you give full play to the role of the cable ties and allow them to better bundle items.