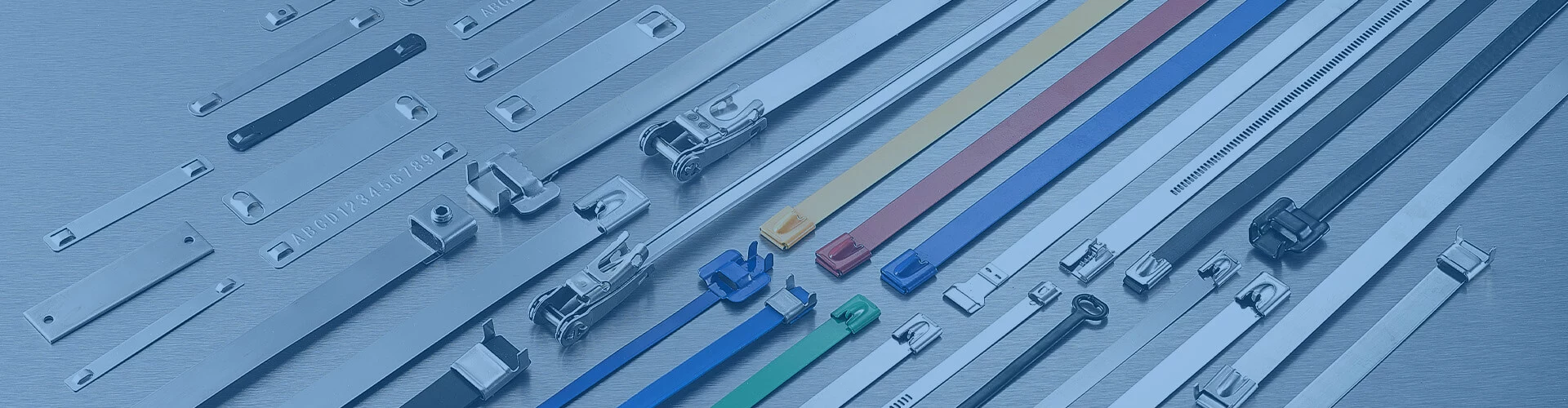

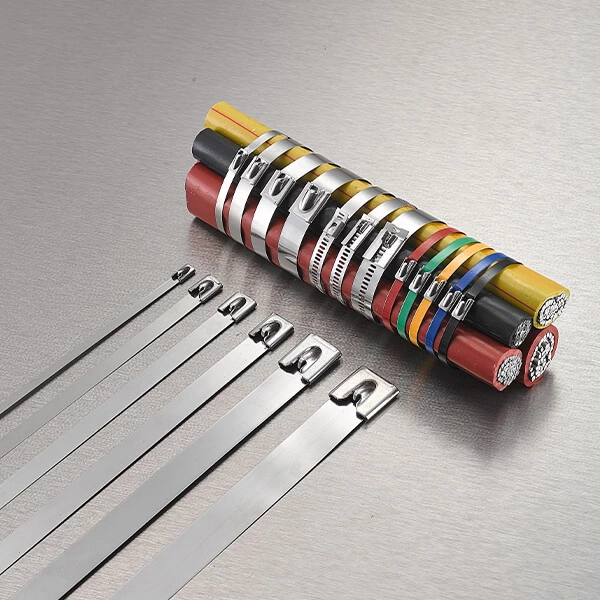

Stainless Steel Cable Tie is an industrial product widely used for fixing, bundling and fixing materials in the fields of power, telecommunications, marine, petrochemicals, etc. It is made of stainless steel material, so it has excellent performance in special environments. This article will explore its production process to help everyone understand its manufacturing process.

1. Raw material preparation

Stainless steel material: The main raw material of cable ties is stainless steel strip, usually made of stainless steel materials such as AISI 304 or AISI 316.

Packaging material: Cable ties usually require packaging materials such as reels or coils to ensure that the product can be transported and used smoothly.

2. Cold drawing and hot rolling

The production of cable ties usually includes two main stages: cold drawing and hot rolling:

Cold drawing: First, the stainless steel raw material undergoes a cold drawing process to stretch the stainless steel billet into the desired shape and size. This process helps to improve the strength and hardness of the material.

Hot rolling: Next, the cold-drawn stainless steel billet undergoes a hot rolling process to heat it to a certain temperature, and then it is formed and stretched through a rolling equipment to obtain the desired width and thickness.

3. Cutting and trimming

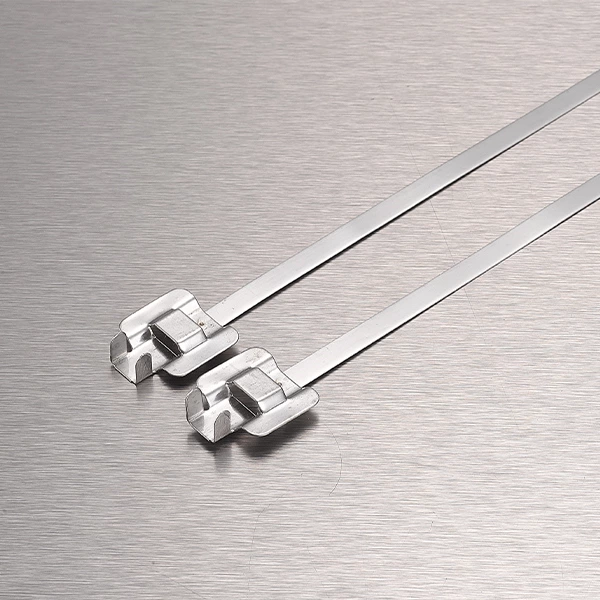

After cold drawing and hot rolling, the stainless steel billet will be further cut and trimmed to obtain the required length and shape. Cutting and trimming usually use processes such as laser cutting or mechanical cutting.

4. Surface treatment

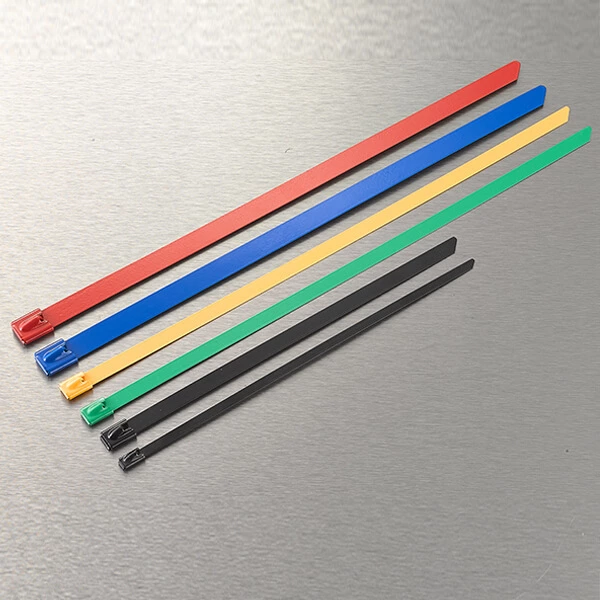

The surface of the stainless steel cable tie needs to be treated to improve its corrosion resistance and appearance quality. Surface treatment processes include: pickling, polishing and electroplating.

5. Marking and marking

Cable ties usually need to be engraved or marked so that the product specifications, batch information, etc. can be identified when used. Marking usually uses technologies such as laser engraving or chemical etching engraving.

6. Packaging and delivery

The stainless steel cable ties that have gone through all production and processing steps will be packaged and marked and ready for delivery. Packaging is usually based on customer requirements and product specifications, and can be reels, coils, trays or other methods.

7. Quality control

Quality control is crucial throughout the production process. Cable ties need to undergo strict quality inspections, including appearance inspection, size measurement, tensile testing, corrosion resistance testing, etc. Only products that pass the quality inspection can leave the factory.

Eight, R&D and Innovation

The production of cable ties requires not only strict quality control, but also continuous R&D and innovation. Manufacturers are constantly working to improve materials and processes to provide more durable and higher-performance products to meet the needs of different industries and applications.

The above steps ensure that stainless steel cable ties have superior corrosion resistance, strength and wear resistance, and can be used reliably in various harsh environments. With the continuous advancement of technology, the quality and performance of cable ties will continue to be improved and enhanced to meet the ever-changing market needs.