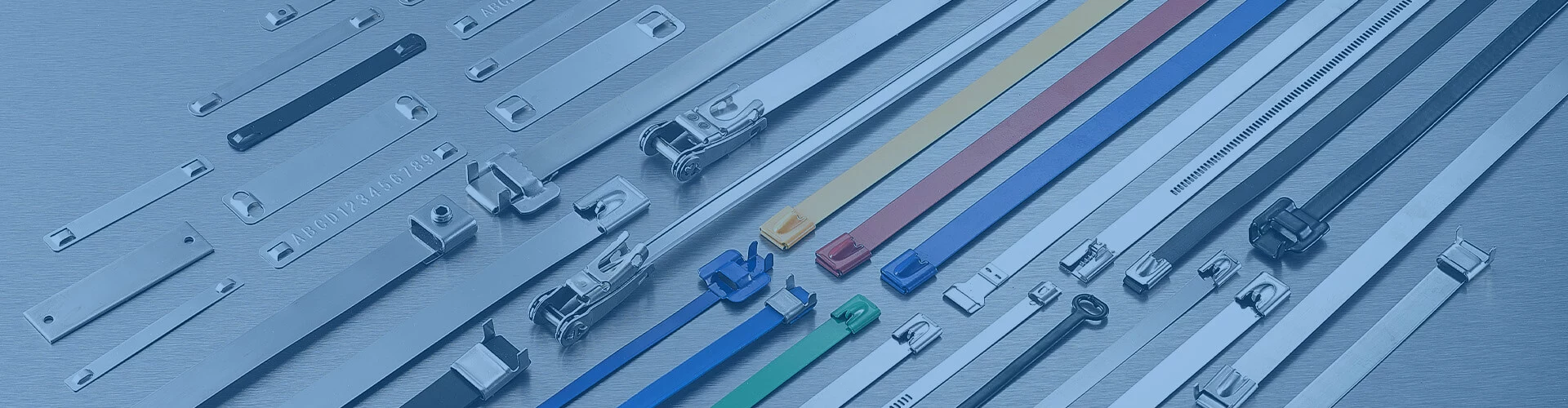

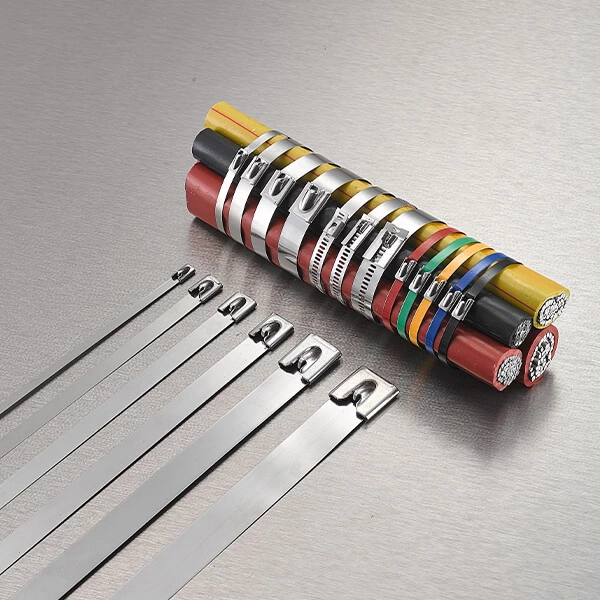

Stainless Steel Cable Tie is an industrial material commonly used for bundling, fixing and tying cables, pipes, pipelines and equipment. They are suitable for a variety of harsh environments and industrial applications. When purchasing cable ties, there are some key factors to consider to ensure that they can meet specific needs and requirements. This article will introduce the selection method of cable ties to help you easily purchase this product.

1. Understand the basic characteristics of cable ties

Before choosing cable ties, you need to understand their basic characteristics. Here are some key features of cable ties:

Corrosion resistance: Cable ties have excellent corrosion resistance and are suitable for use in humid, corrosive gas or liquid environments.

High temperature resistance: Cable ties can withstand high temperature environments and are generally able to work at temperatures above 500°F (260°C).

Abrasion resistance: They have high abrasion resistance and are not easily susceptible to mechanical damage or wear.

High strength: Cable ties have high tensile strength and can maintain a stable cable bundling effect.

2. Determine the needs and applications

Before purchasing plastic-sprayed stainless steel cable ties, you need to clarify the needs and specific application scenarios of the product. Here are some questions to help you better understand the needs:

Application environment: What type of environment will the cable tie be used in? For example, is it indoors or outdoors, and are there corrosive chemicals present?

Temperature requirements: Does your application need to withstand high temperatures? If so, you need to consider the temperature tolerance range of the cable tie.

Tension requirements: What is the tension requirement of the cable tie? This will affect the selection of the width and thickness of the cable tie.

Length and width: Determine the length and width of the cable tie required. Different applications may require cable ties of different sizes.

3. Choose the right model and specifications

Once the needs and applications are clear, you can choose the right cable tie model and specifications. Here are some factors to consider:

Width and thickness: The width and thickness of the cable tie will affect its tension and stability. Choose the appropriate size according to the needs of the application.

Length: Plastic-sprayed stainless steel cable ties of different lengths are suitable for different sizes of cable ties. Make sure to choose a cable tie that is long enough to meet your needs.

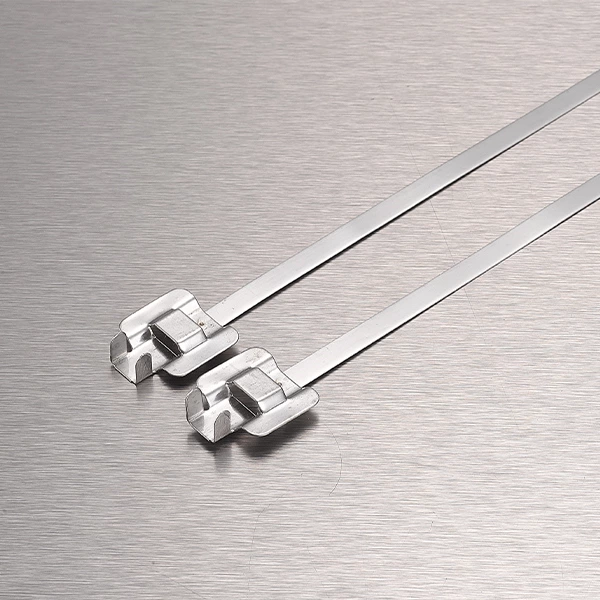

Locking mechanism: Cable ties usually have two locking mechanisms, ball lock and flat lock. Choose the right type according to your needs.

Surface treatment: Some cable ties have additional surface treatments, such as spraying, coating or closed design, to provide additional corrosion resistance or anti-slip.

Fourth, consider safety and reusability

In some cases, cable ties need to have a certain degree of safety and reusability. These requirements can be met in the following ways:

Self-locking design: Choose cable ties with a self-locking design to ensure that they will not unlock themselves after being locked once.

Reusability: Some cable ties have reusable properties and can be opened and closed multiple times. This is useful for applications that require frequent adjustments.

If your application requires a special size, shape or design of sprayed stainless steel cable ties, you can consider a customized solution. Customized cable ties can meet specific needs, but usually require additional costs and delivery time.