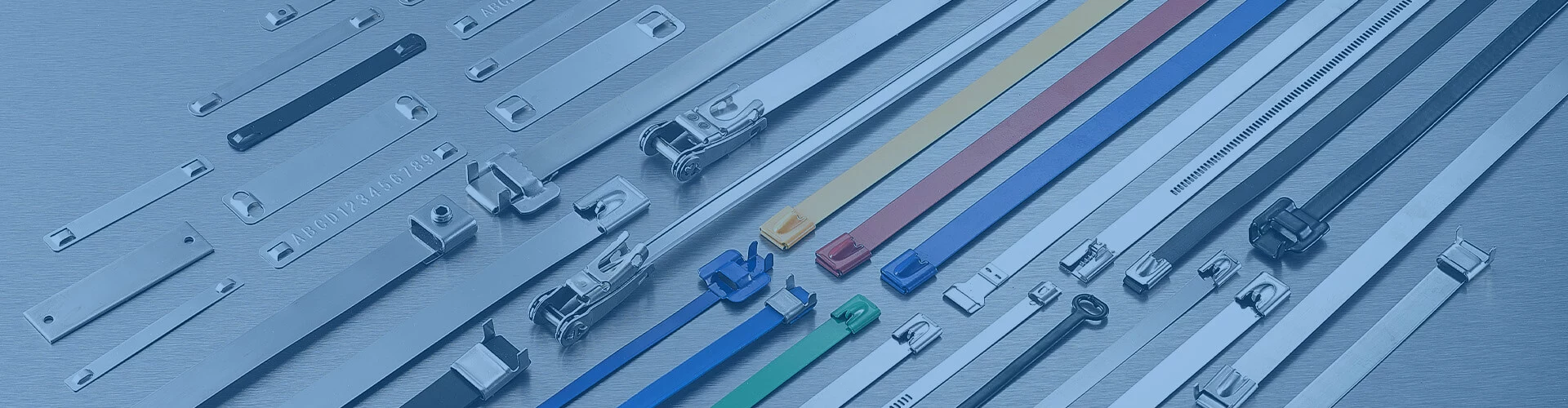

Stainless Steel Cable Tie is a versatile fixing and tying tool, which is widely used in various industries and fields. They are made of stainless steel material and have the characteristics of corrosion resistance, high temperature resistance and high strength. This article will explore the specifications, application fields and selection methods of cable ties.

The specifications of cable ties include the following aspects:

1. Length: The length of cable ties is usually between 100mm and 1000mm, and the specific length can be customized as needed.

2. Width: The width is generally between 4.6mm and 12mm, and cable ties of different widths are suitable for restraints of different sizes.

3. Material: Cable ties are mainly made of stainless steel (usually 304 or 316 grade) to ensure that they have corrosion resistance and high temperature resistance.

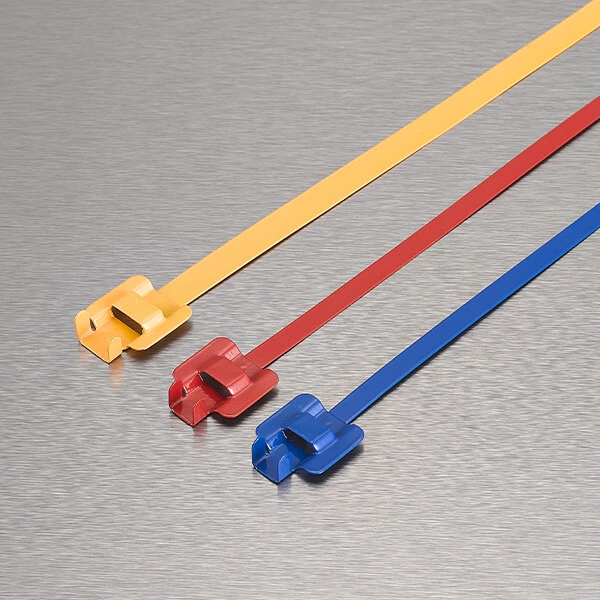

4. Surface treatment: Some cable ties have additional surface treatment, such as nylon sleeves or coatings, to provide additional protection or reduce friction.

5. Tensile strength: The tensile strength of cable ties is a key parameter, usually between 50 pounds (about 22.68 kg) and 250 pounds (about 113.4 kg).

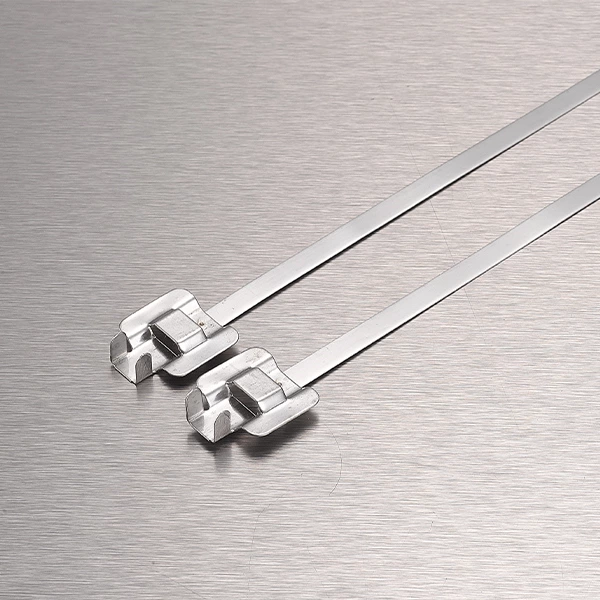

6. Locking mechanism: The locking mechanism of stainless steel cable ties usually adopts a ball lock or a self-locking mechanism with ears to tighten the cable tie and ensure that it remains in the correct position.

Cable ties have a wide range of applications, including the following:

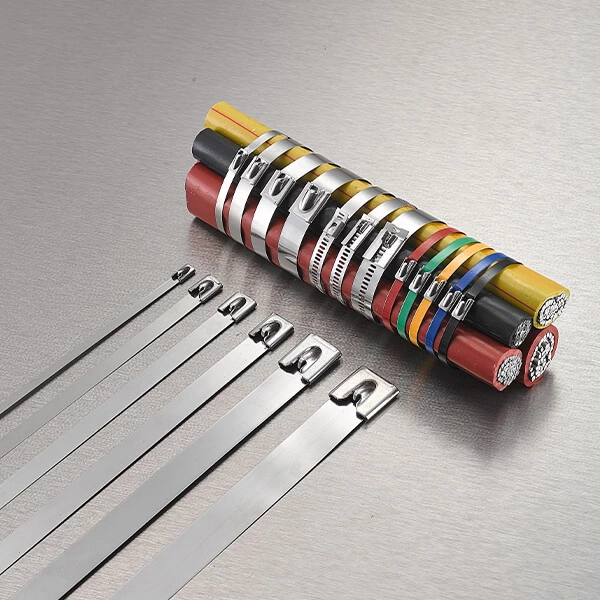

1. Electrical and electronic industries: used to tie wire and cable bundles to neatly and safely organize electrical lines.

2. Food and pharmaceutical industries: used in environments with strict hygiene requirements, such as the fixing and tying of food processing and pharmaceutical equipment.

3. Machinery and manufacturing industries: used to fix, tie and fix mechanical parts such as pipes, pipe brackets and equipment.

4. Environmental protection and water treatment: used to fix and tie water treatment equipment, pipes and pipelines.

5. Automobile and transportation: used in automobile manufacturing and maintenance, fixing exhaust systems, wiring harnesses and parts.

When choosing the right stainless steel cable tie, consider the following factors:

1. Application environment: Determine in what environment the cable tie will be used, including temperature, humidity, and corrosiveness.

2. Reusability: Choose single-use or reusable cable ties as needed.

3. Price and cost-effectiveness: Consider the price and cost-effectiveness of the cable tie to meet budget requirements.

4. Size of the tie: Choose a cable tie of appropriate width and length according to the material and size you want to tie.

5. Tensile strength: Choose a cable tie with appropriate tensile strength according to the needs of the application to ensure that it can withstand the required load.

6. Locking mechanism: Consider the type of locking mechanism and choose a ball lock or a self-locking mechanism with ears as needed.

7. Surface treatment: If additional protection or reduced friction is required, choose a cable tie with appropriate surface treatment.

Stainless steel cable ties are a versatile tool that is widely used in a variety of applications, from the electronics and electrical industries to manufacturing and construction. Correctly selecting the appropriate specifications and types of cable ties is the key to ensuring work efficiency and safety. By understanding application needs, considering environmental conditions and following maintenance recommendations, you can ensure your cable ties will perform reliably in a variety of conditions.