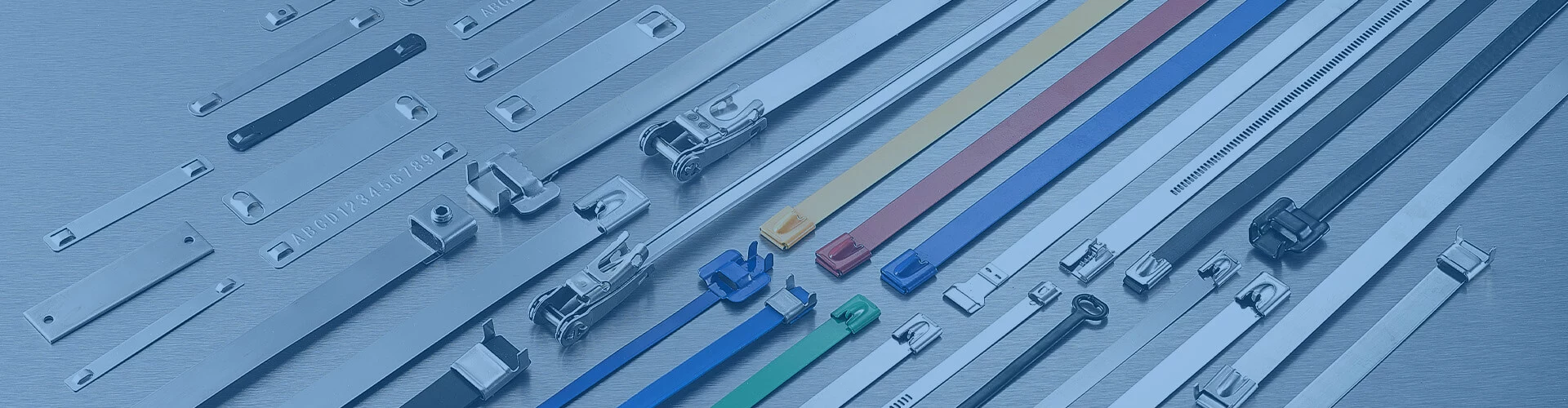

Many people may not have noticed that Stainless Steel Cable Tie is of great use in many industries, especially in the shipbuilding, aviation, electric power, petrochemical, cable and other industries, where it plays an important fixing role. It is precisely because of the large market demand for cable ties that some inferior cable ties have appeared on the market. These cable ties are not only different from high-quality cable ties in terms of material selection, but also in terms of manufacturing process. Therefore, as a user, it is important to learn to identify inferior cable ties when purchasing. How to identify? The manufacturer tells you.

1. Look at the material

Inferior cable ties are generally made of less sturdy materials, which are prone to looseness or breakage. Therefore, before purchasing cable ties, you can first check the characteristics of the material such as firmness and hardness. Generally speaking, high-quality cable ties will use 316L stainless steel with higher hardness, and their corrosion resistance and performance will be better after surface treatment.

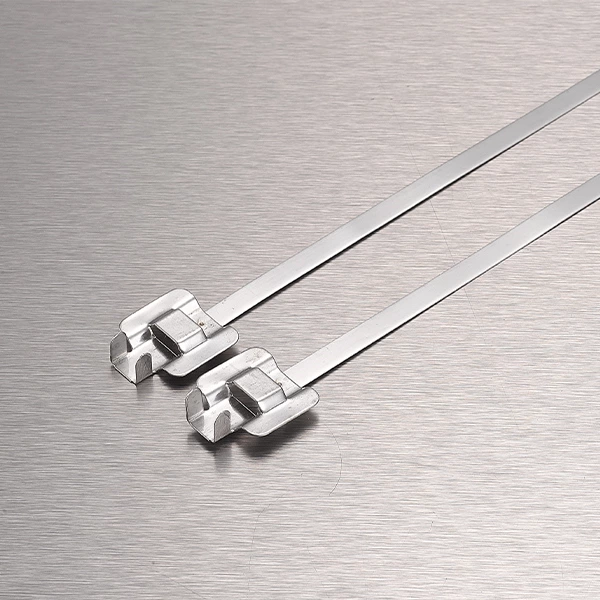

2. Check the surface treatment

The surface treatment of stainless steel cable ties is also one of the important factors in identifying high-quality stainless steel cable ties. During the production process, inferior cable ties often use a simpler and rougher treatment method, while high-quality straps undergo optimized surface treatment to improve their performance and service life. Therefore, when selecting cable ties, you can observe factors such as the brightness and smoothness of the surface to judge the quality of its surface treatment.

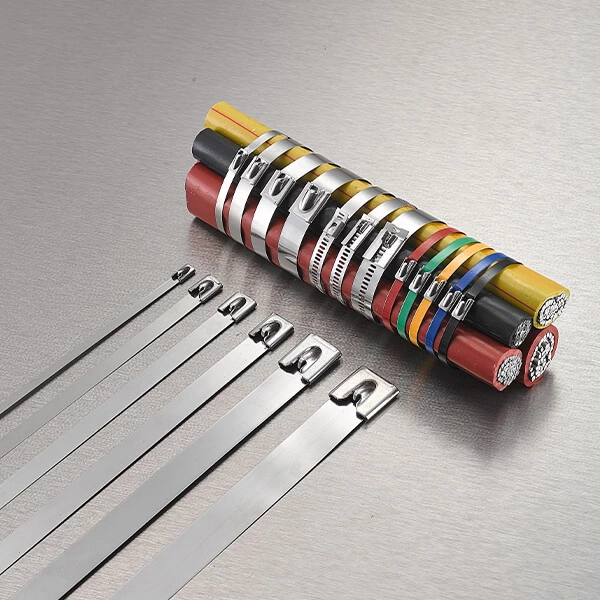

3. Check strength

In addition to the material and surface treatment, the strength of the cable tie is also one of the important factors in judging its quality. High-quality cable ties use high-quality raw materials and mature processing technology, and have relatively high strength and hardness.

Inferior cable ties use low-quality raw materials and simple manufacturing processes, and their strength is often low, easy to break or have other problems. Therefore, when selecting cable ties, you can use tensile tests and other methods to test their strength and hardness and other characteristics to judge their quality and reliability.

Stainless steel cable ties are a fixing tool that requires high quality and good craftsmanship. The inferior cable ties on the market not only have safety hazards, but also affect work efficiency and product quality. You need to carefully select cable ties on weekdays and choose suppliers with brands and reputations for purchase.

At the same time, pay attention to the inspection of factors such as product material, surface treatment and strength to avoid buying inferior products. Only in this way can we get high-quality cable ties and give full play to their excellent fixing effect to improve work efficiency and safety.

The skills of selecting manufacturers are diverse, and they should be mastered when purchasing stainless steel cable ties, which are more commonly used tools. The manufacturer tells you: By looking at the material, checking the surface treatment and checking the strength, you can better identify inferior cable ties and buy high-quality cable ties. I hope that when using them, the quality of the cable ties is qualified.