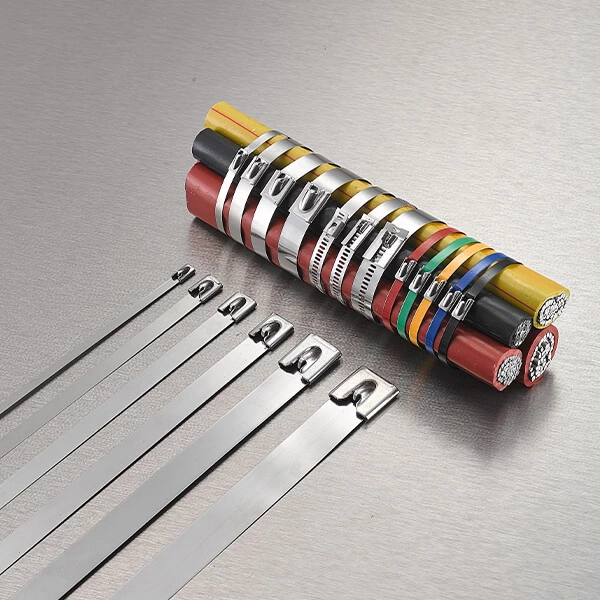

Stainless Steel Cable Tie has the advantages of strong corrosion resistance, light weight and long service life, which makes it a common fixing accessory in the fields of electricity, electronics, communications, aviation, petroleum, metallurgy, etc. However, during use, the surface treatment of cable ties is also a very important part. Today, the editor will introduce several treatment methods for stainless steel cable ties?

Why do you need to treat the surface of cable ties?

Surface treatment of cable ties can provide them with better surface protection and aesthetics. During the production process, there may be scratches or rust on the surface of the cable ties, which will reduce its performance in terms of plasticity, tension and maintenance aesthetics.

In addition, the surface treatment of cable ties is intended to improve its corrosion resistance and antioxidant ability, allowing it to operate stably for a long time in harsh environments, and avoid corrosion problems in high temperature, humidity and strong acid and alkali environments.

Treatment method

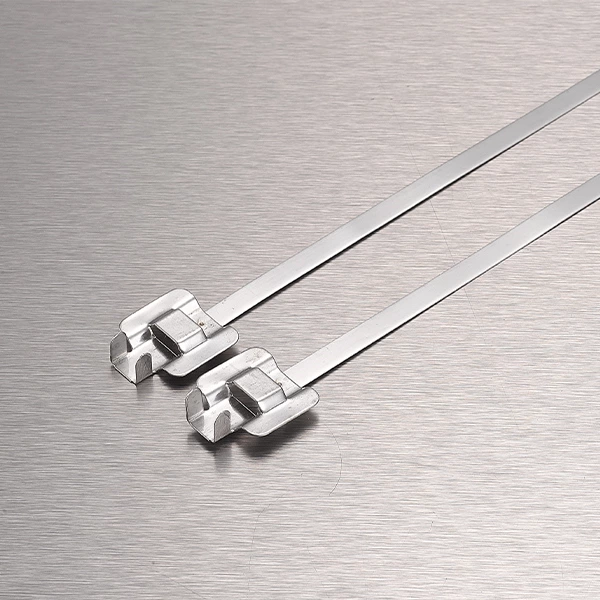

1. Polishing treatment

Polishing treatment of stainless steel cable ties is a common surface treatment method. This treatment method usually uses mechanical equipment to grind the surface of the cable tie to obtain a smooth and shiny surface. Polishing treatment can not only improve its strength, but also improve its appearance quality and enhance corrosion resistance.

2. Sandblasting

Sandblasting is a process of spraying sand, glass balls or ceramic particles on the surface of cable ties with a high-pressure spray gun. This treatment method can eliminate problems such as rust and scratches on the surface, while enhancing the corrosion resistance, aesthetics and antioxidant capacity of the cable ties.

3. Anodic oxidation

Anodic oxidation is a surface treatment method obtained by treating the surface of stainless steel cable ties by electrolysis. During the treatment process, the anode prepared by titanium, aluminum, etc. acts as an electrode, and the electrolyte is an aqueous solution containing corrosive substances such as hydrochloric acid.

In this way, the surface coating can enhance its corrosion resistance and overall performance, while also improving its aesthetics and antioxidant capacity.

The surface treatment of cable ties is very important during use, and it involves many aspects such as the strength, plasticity, corrosion resistance, and antioxidant capacity of the cable ties. If properly handled, the cable ties can better adapt to the use requirements in various harsh environments, thereby improving their overall performance and service life.

Although the surface treatment of stainless steel cable ties will increase costs for manufacturers, the appearance and corrosion resistance of treated cable ties are far superior to those that have not been surface treated. Therefore, if the manufacturer's conditions permit, it is recommended that all cable ties produced be surface treated.