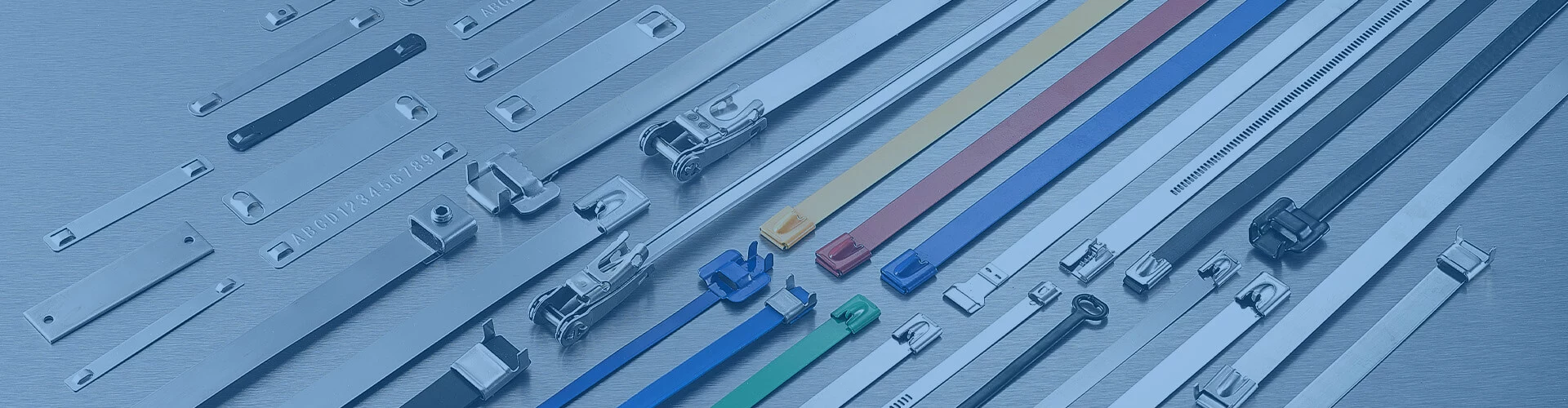

Stainless Steel Cable Tie is a commonly used fixing tool, widely used in various industries and fields. Cable ties of different specifications are suitable for different application scenarios and needs. This article will introduce the common specifications of stainless steel cable ties as well as their characteristics and application fields.

Common specifications:

Width: The width of the cable tie is usually between 5mm and 12mm, and common specifications include 5mm, 8mm, 10mm and 12mm.

Thickness: The thickness of the cable tie is usually between 0.25mm and 0.5mm, and common specifications include 0.25mm, 0.3mm and 0.5mm.

Length: The length of the cable tie can be customized as needed, and the general length range is 100mm to 1500mm.

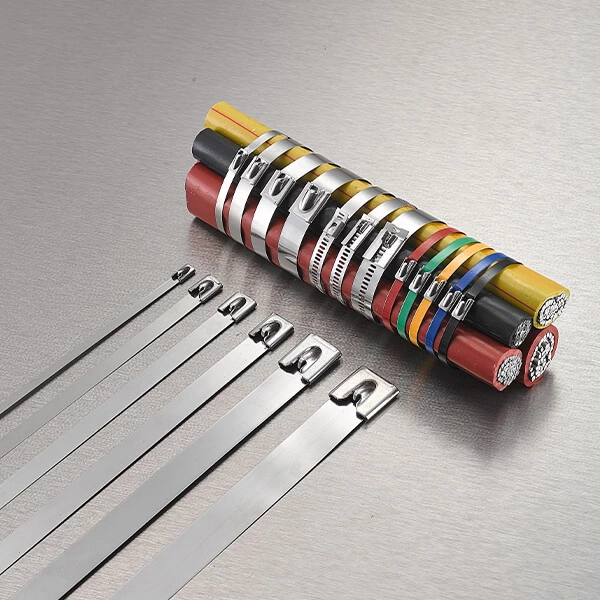

Strength grade: The strength grade of stainless steel cable ties can be selected according to needs. Common strength grades include 304 stainless steel and 316 stainless steel.

Features:

Corrosion resistance: The cable tie is made of stainless steel, has excellent corrosion resistance, and can be used for a long time in harsh environments.

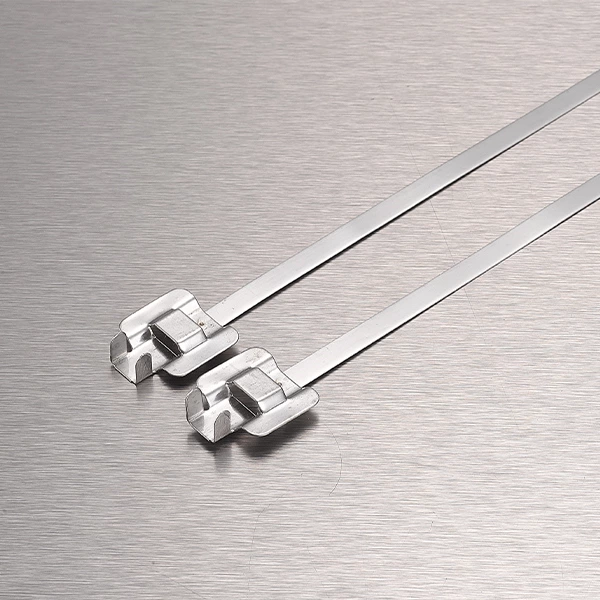

High strength: Cable ties have high strength and tensile strength, can firmly fix objects, and are not easy to break or loosen.

High temperature resistance: Cable ties can maintain stable performance in high temperature environments and are not easy to deform or damage.

Abrasion resistance: The surface of the cable ties is smooth and it is not easy to damage the surface of the tied object.

Weather resistance: Cable ties can resist the erosion of natural environments such as ultraviolet rays, wind and rain, and have good weather resistance.

Application areas:

Electrical equipment: Stainless steel cable ties are suitable for fixing and arranging wires, cables and electrical equipment to ensure the safety and reliability of electrical connections.

Mechanical equipment: Cable ties can be used to fix pipes, connectors and other mechanical parts to ensure the stability and safety of mechanical equipment.

Petrochemical: The corrosion resistance of cable ties makes them widely used in the field of petrochemicals. It can be used to fix and tie pipes, valves, pumps and other equipment, as well as seal and insulate in the chemical production process.

Communication equipment cable ties are widely used in the cable management and fixation of communication equipment to ensure the stability and reliability of the communication system.

Architectural decoration: Cable ties can be used for fixing and supporting in architectural decoration, such as fixing pipes, wire troughs, lighting equipment, etc.

Other fields: Stainless steel cable ties can also be used in ships, railways, electronic devices, power equipment, agriculture and other fields.

When choosing cable tie specifications, the following factors need to be considered according to actual needs:

Stress and load of cable ties: According to the weight and stress of the object to be fixed, select the appropriate width and thickness of the cable ties to ensure sufficient strength.

Length of cable ties: According to the size of the object to be tied, select the appropriate length of the cable ties. Pay attention to leaving appropriate margins to ensure that the cable ties can be tightened firmly.

Environmental requirements: According to the temperature, humidity and corrosiveness of the use environment, select stainless steel materials with corresponding corrosion resistance.

Stainless steel cable ties have the characteristics of corrosion resistance, high strength and high temperature resistance, and are widely used in various fields. By selecting cable ties of appropriate specifications and materials, it can meet the fixing, binding and packaging needs of different fields, and improve work efficiency and product quality. When choosing, the actual application scenarios and requirements should be comprehensively considered, and it should be ensured that the selected cable ties meet the corresponding standards and quality requirements.