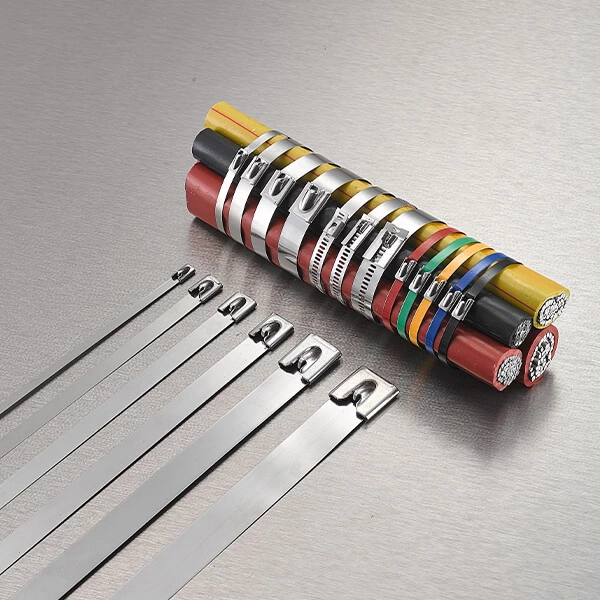

Stainless Steel Cable Tie has excellent corrosion resistance and high strength, so it has become a commonly used fastening tool in industry and life. However, many people find that sometimes it rusts during use, and rust will affect its use effect and life. This article will introduce the reasons and prevention methods of its rust.

Cause analysis:

1. Material quality problem: The quality of the cable tie directly affects its corrosion resistance. If the selected stainless steel material is of unqualified quality or contains high impurities, it is easy to cause the cable tie to rust.

2. Influence of corrosive environment: Cable ties are used in humid, high temperature, strong acidity and alkalinity, and high chloride ion content environments, which are easily affected by corrosion and rust.

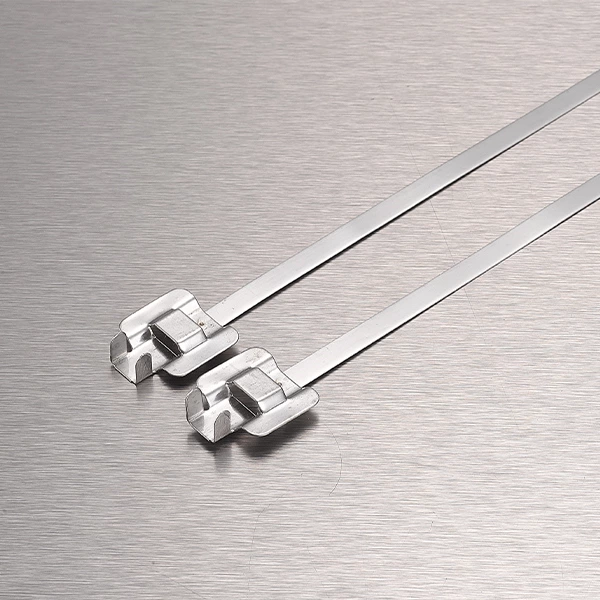

3. Incorrect installation: Incorrect installation methods, such as over-tightening cable ties or direct contact with other metal materials, may cause the cable tie to be subjected to external stimulation and pressure, causing rust problems.

4. Surface damage: If the surface of the stainless steel cable tie is scratched, worn or delaminated, it will destroy its self-repairing ability, thereby increasing the risk of rust.

Prevention methods:

1. Choose high-quality materials: When purchasing cable ties, you should choose products with reliable quality and meet standard requirements. High-quality stainless steel materials can provide better corrosion resistance and reduce the risk of rust.

2. Correct installation and use: When installing stainless steel cable ties, pay attention to the appropriate tension, do not be too tight or too loose, so as not to damage the surface of the cable ties. At the same time, follow the correct installation method to ensure that the cable ties are not squeezed or scratched by external objects to reduce the possibility of damage and rust.

3. Use anti-corrosion coating: You can consider applying an anti-corrosion coating on the surface of stainless steel cable ties to provide an additional layer of protection to reduce the risk of corrosion and rust.

4. Avoid corrosive environments: Try to avoid using cable ties in humid, high-temperature, acidic and alkaline environments with high chloride ion content. If you must use it in these environments, you can choose special stainless steel materials with higher corrosion resistance, such as 316 stainless steel.

5. Regular cleaning and maintenance: Regularly clean the dust, dirt and chemical residues on the surface of the cable ties to keep its surface clean. If surface damage is found, repair or replace it in time.

6. Prevent contact with other metals: Avoid direct contact between cable ties and other metal materials, especially metals with high corrosiveness. Plastic gaskets or insulating materials can be used to isolate stainless steel cable ties from contact with other metals to reduce the risk of corrosion.

In short, there are many reasons for stainless steel cable ties to rust. If you want to prevent them from rusting, you can start with the causes of rust, which can effectively reduce the occurrence of rust problems, extend their service life, and ensure their stable and reliable fastening effect.